Our clients

Just a few words from our clients

Toshiba Digital Solutions Corporation

Using ProLaris for more than 18 months, we are really satisfied with its performance. ProLaris gave us clear priority on our production floor and brought shorter lead times by improving the flow and the production pace. ProLaris assumes an important role in processing our production .

ICT Infrastructure Services Center

FLSmidth

D Quantum

As a long time customer (almost 3 years), the service and support level are stellar.

ProLaris is an amazing tool (secure, reliable, cost effective) – it’s invaluable to our company.

The product just works seamlessly with our legacy systems and give us full visibility and automation.

Treixedo

VP R&D

CTO

VP DevOps

Project manager

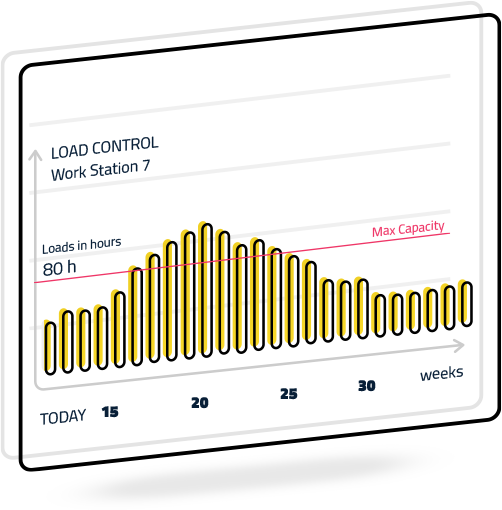

VP Business development

About BUFFERS.AI

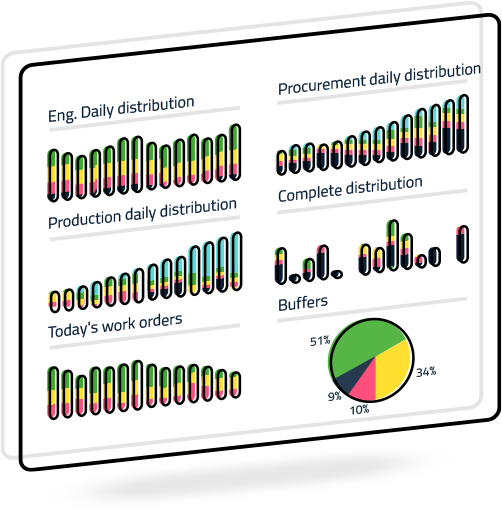

Uncertainty is the root cause for the core problem in supply chains. Common approach to deal with uncertainty is to rely on detailed “accurate” projections thus imposing certainty on uncertain reality. Buffers.ai innovative approach is protecting uncertainty with dynamic buffers according to real time demand-sensing capabilities and by bottlenecks identifications and load control. We orchestrate a smooth flow of goods across the manufacturing floor and supply chain by implementing revolutionary algorithms that react to real market demand. We provide greater visibility of daily product performance and help companies to automatically define the right inventory levels required at each stock location and production process. Our system is equipped with features to support end to end supply chain from raw materials, semi-finished goods, sub-assemblies and finish goods manufacturing & warehousing (make to order - MTO, make to stock - MTS, engineering to order - ETO, and combinations of the three) and procurement processes for any supply chain/retail architecture. Our system integrates easily, very fast and seamlessly to any ERP or legacy system, materializing huge benefits in just few weeks. Moreover, we are creating a “Unified Manufacturing and Supply Chain” that can leverage and give access to its execution and control features to different companies (or the same company using different ERPs) in the same ECOsystem. An advanced state-of-the-art SaaS-based cloud solution, that can handle any data volume, enables you to scale up the infrastructure as your business grows and boosts business results by utilizing your existing assets, taking into account your specific business constraints.

Our Advantages

Increased sales (significantly less/No stock-outs)

- Happy customers (better level of service/availability of goods)

- Better on time delivery

- Reduce costly initiatives (discounts, incentives, advertising etc.) to get rid of excessive stocks

- Reduce dead and slow tail

- Increase Inventory Turns (more sales coupled with less overall inventories)

- Increased ROI

- Reduction in obsolete products

- Exposed production capacity

- Reduce Expedited shipments

- Reduce Cross shipping

- Reduce over time

Full synchronization between production/purchasing and real demand

- Reveal excess production capacity – huge saving on new investments

- Significantly faster response to market demands and special campaigns

- No rescheduling – connecting BOM (RMs & packaging) to real demand

- Advanced Dynamic Demand Sensing, can deal with very different demand patterns

- Extremely better visualization – critical for correct decision making in complex networks

- Potential to expand the breadth of SKU’s at the customer, supported by the reduction in required inventory levels

- Full synchronization across the entire supply chain with a single priority system

- Much better control in Engineering and Procurement processes